LESS PRESSURE, MAXIMUM EFFICIENCY

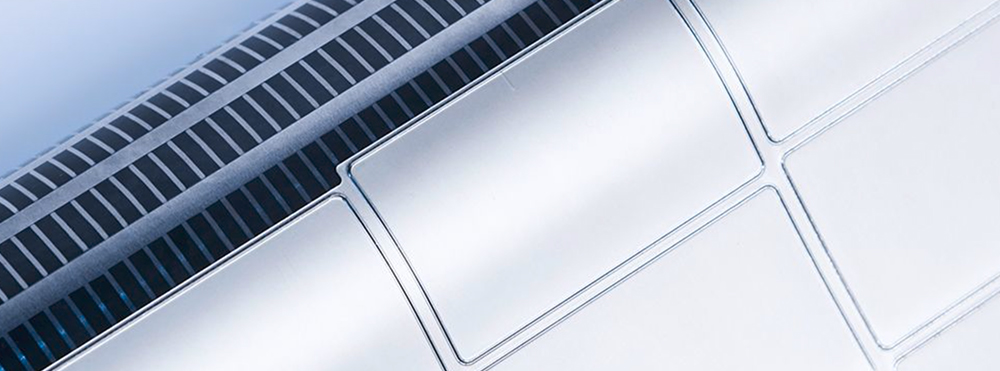

Very often, labels include a high percentage of crosslines, e.g. rectangles. These shapes are fundamentally disadvantageous for die-cutting, however, and often cause problems in the die-cutting of lines across web direction. Help is at hand here with our ProShift® technology.

In a conventional, symmetrical arrangement of labels, the fact is that the greater the number and length of the crosslines, the more pretension is needed for these lines to be cut cleanly. With ProShift® flexible dies, however, the impressions are staggered in web direction. This reduces the length of the simultaneously cutting cross-lines, so that the cutting pressure can be considerably reduced.

----------------------

The advantages of the ProShift® principle are not just in die-cutting. The staggered structure of the labels also has a positive influence on the printing results and increases overall efficiency:

- perfect cutting results with minimum pretension

- simple and stable matrix stripping

- considerable reduction in cutting noise

- longer lifetime of flexible dies and other machine parts

- shorter setup times due to simple adjustment of cutting pressure

- lower dot gain in printing and reduced "bouncing" of printing cylinders

- higher production speeds possible in many cases